ASTM E2656-25 药用水总有机碳属性的实时释放测试

VIP免费

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards,Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade(TBT)Committee.

Designation:E2656-25

INTERNATIOMAL

Standard Practice for

Real-time Release Testing of Pharmaceutical Water for the

Total Organic Carbon Attribute

This standard is issued under the fixed designation E2656;the number immediately following the designation indicates the year of

original adoption or,in the case of revision,the year of last revision.A number in parentheses indicates the year of last reapproval.A

superscript epsilon(ε)indicates an editorial change since the last revision or reapproval.

1.Scope

1.1 This practice establishes an approach to the real-time

release testing(RTRT)of pharmaceutical water based on the

total organic carbon(TOC)attribute using on-line total organic

carbon(OLTOC)instrumentation that is in agreement with

current regulatory thinking.

1.2 This practice is harmonized with or supports the con-

cepts of relevant ASTM International Committee E55 on

Manufacture of Pharmaceutical Products standards,ICH Har-

monized Tripartite Guidelines,the U.S.FDA PAT Guidance,

and U.S.FDA Pharmaceutical CGMPs.

1.3 This practice does not provide general guidance infor-

mation for pharmaceutical procedures that are considered

standard practice in the pharmaceutical industry.This practice

provides specific guidance for non-standardized procedures.

1.4 This practice does not address the user's various internal

procedures for risk,change,or quality management systems.

The overall project effort associated with this practice shall be

proportional to the overall risk of failing the pharmaceutical

water's TOC concentration specification.

1.5 This practice does not purport to establish how to

comply with pharmacopeias.The RTRT methodology selected

must assure compliance with the user's current required

pharmacopeias.However,compliance with pharmacopeia TOC

methods is not necessarily sufficient to meet current regulatory

expectations for RTRT.

1.6 This practice does not purport to substitute for or replace

compendial bioburden testing requirements.It is strictly appli-

cable to the TOC attribute of water quality.

1.7 This standard does not purport to address all of the

safety concerns,if any,associated with its use.It is the

responsibility of the user of this standard to establish appro-

priate safety,health,and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

!This practice is under the jurisdiction of ASTM Committee E55 on Manufac-

ture of Pharmaceutical and Biopharmaceutical Products and is the direct responsi-

bility of Subcommittee E55.12 on Process Applications.

Current edition approved Jan.1,2025.Published January 2025.Originally

approved in 2010.Last previous edition approved in 2016 as E2656-16.DOI:

10.1520/E2656-25.

1.8 This international standard was developed in accor-

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

Development of International Standards,Guides and Recom-

mendations issued by the World Trade Organization Technical

Barriers to Trade(TBT)Committee.

2.Referenced Documents

2.1 ASTM Standards:²

E2281 Practice for Process Capability and Performance

Measurement

E2363 Terminology Relating to Manufacturing of Pharma-

ceutical and Biopharmaceutical Products in the Pharma-

ceutical and Biopharmaceutical Industry

E2500 Guide for Specification,Design,and Verification of

Pharmaceutical and Biopharmaceutical Manufacturing

Systems and Equipment

E2537 Guide for Application of Continuous Process Verifi-

cation to Pharmaceutical and Biopharmaceutical Manu-

facturing

D4839 Test Method for Total Carbon and Organic Carbon in

Water by Ultraviolet,or Persulfate Oxidation,or Both,and

Infrared Detection

D5173 Guide for On-Line Monitoring of Total Organic

Carbon in Water by Oxidation and Detection of Resulting

Carbon Dioxide

D5904 Test Method for Total Carbon,Inorganic Carbon,and

Organic Carbon in Water by Ultraviolet,Persulfate

Oxidation,and Membrane Conductivity Detection

D5997 Test Method for On-Line Monitoring of Total

Carbon,Inorganic Carbon in Water by Ultraviolet,Persul-

fate Oxidation,and Membrane Conductivity Detection

D6317 Test Method for Low Level Determination of Total

Carbon,Inorganic Carbon and Organic Carbon in Water

by Ultraviolet,Persulfate Oxidation,and Membrane Con-

ductivity Detection

²For referenced ASTM standards,visit the ASTM website,www.astm.org,or

contact ASTM Customer Service at www.astmorg/contact.For Annua Book of

ASTM Standards volume information,refer to the standard's Document Summary

page on the ASTM website.

Copyrght OASTM International,100 Barr Harbor Drive,PO Box C700,West Conshohocken,PA 19428-2959.United States

工

2

2.2 Other Reference Documents:

ICH Q2(R2)Validation of Analytical Procedures:Text and

Methodology ³

ICHQ7 Good Manufacturing Practice Guide for Active

Pharmaceutical Ingredients³

ICHQ8(R2) Pharmaceutical Development³

ICHQ9(R1) Quality Risk Management³

ICHQ10 Pharmaceutical Quality System³

ISO 15839 Water Quality —On-line Sensors/Analyzing

Equipment for Water:Specifications and Performance

Tests⁴

JP Chapter<2.59> Test for Total Organic Carbon⁵

Ph.Eur.Chapter<2.2.44> Total Organic Carbon in Water

for Pharmaceutical Use⁶

U.S.FDA Part 11 Guidance Guidance for Industry:Part 11,

Electronic Records;Electronic Signatures —Scope and

Application ⁷

U.S.FDA PAT Guidance Guidance for Industry:PAT—A

Framework for Innovative Pharmaceutical Development,

Manufacturing,and Quality Assurance⁷

U.S.FDA Pharmaceutical CGMPs Pharmaceutical CGMPs

for the 21st Century —A Risk-Based Approach⁷

U.S.FDA Procedures and Methods Validation Guidance for

Industry:Analytical Procedures and Methods Validation

Chemistry,Manufacturing,and Controls Documentation⁷

U.S.FDA Process Validation Guidance Guidance for Indus-

try:Process Validation:General Principles and Practices⁷

USP Chapter<643> Total Organic Carbon(TOC)⁸

USP Chapter<1225> Validation of Compendial Procedures⁸

USP Chapter<1226> Verification of Compendial Proce-

dures ⁸

USP Chapter<1231>Water for Pharmaceutical Purposes⁸

USP Guidance<1058> Analytical Instrument Qualification⁸

3.Terminology

3.1 For definitions of terms specific to this standard,refer to

the Terminology sections of Practice E2281,Terminology

E2363,and Guide E2500. Refer to ICHQ2(R2)for method

validation terminology.

4.Summary of Practice

4.1 This practice provides the user with sufficient guidance

for developing the scientific and risk-based information nec-

3Available from International Conference on Harmonisation of Technical

Requirements for Registration of Pharmaceuticals for Human Use(ICH),ICH

Secretariat,c/o IFPMA,15 ch.Louis-Dunant,P.O.Box 195,1211 Geneva 20,

Switzerland,http://www.ich.org.

4Available from International Organization for Standardization(ISO),1,ch.de

la Voie-Creuse,Case postale 56,CH-1211,Geneva 20,Switzerland,http://

www.iso.ch.

5Available from Japanese Pharmacopoeia(JP),Standards Division,Office of

Compliance and Standards,Pharmaceuticals and Medical Devices Agency(PMDA),

Shin-kasumigaseki Building,3-3-2,Kasumigaseki,Chiyoda-ku,Tokyo 100-0013,

Japan,http://www.std.pmda.go.jp.

⁶Available from European Pharmacopoeia(Ph.Eur.),7 allee Kastner,CS 30026,

F67081 Strasbourg,France,http://www.pheur.org.

7Available from Food and Drug Administration (FDA),5600 Fishers Ln.,

Rockville,MD 20857,http://www.fda.gov.

8Available from U.S.Pharmacopeia(USP),12601 Twinbrook Pkwy.,Rockville,

MD 20852-1790,http://www.usp.org.

essary to make informed decisions on the implementation,

continuous verification,and continuous improvement of a

system to provide the real-time release testing of pharmaceu-

tical water using on-line total organic carbon(RTRT-OLTOC)

instrumentation that meets pharmaceutical water TOC specifi-

cations.This guidance is based on Practice E2281,Terminol-

ogy E2363 ,and Guide E2500 standards as well as

ICH Q2(R2),ICH Q7,ICH Q8(R2),ICH Q9(R1),and

ICH Q10 guidelines.The following steps are required to meet

the objectives of this practice.

4.1.1 Technical Evaluation—Evaluate and understand water

systems,TOC measurement technologies,and the related

regulatory requirements.

4.1.2 Risk Assessment—Perform quality risk analysis on the

prospective RTRT system designs to establish the sampling

locations representative of the point-of-use.

4.1.3 Data Quality—Ensure the quality of the data from the

TOC measurement system is suitable for the intended use in

the water RTRT system.Ensure equivalency/consistency to

data from existing TOC measurement systems used to release

water to the TOC attribute,if they exist.

4.1.4 Implementation Strategies—Develop process to as-

sure successful implementation of RTRT

4.1.5 Continuous Verification Procedures—Develop quality

control strategies to ensure consistent system performance.

4.1.6 Continuous Process Improvement—Assess and imple-

ment process improvement practices.

5.Significance and Use

5.1 Pharmaceutical water is the most common component

or ingredient used in pharmaceutical and biopharmaceutical

manufacturing.Acceptable purity of the water is important to

the quality of the final pharmaceutical product.TOC concen-

tration is a key indicator and attribute of the purity of this water

and also an important monitor of the overall performance of the

water purification system.TOC analysis is the measurement of

all the covalently bound carbon present in the water,not

including carbon in the form of carbon dioxide(CO₂),bicar-

bonate ion (HCO₃),or carbonate ion(CO₃²),and is reported

as the mass of organic carbon per volume.

5.2 Application of this practice provides pertinent informa-

tion to make informed decisions on the release of water

meeting pharmaceutical TOC concentration specifications.

6.Procedure

6.1 Technical Evaluation:

6.1.1 The overall project scope shall be proportional to the

associated risk of exceeding the pharmaceutical water TOC

concentration specifications.Knowledge and understanding of

the TOC concentration in the water system,the OLTOC

measurement system technology performance,and the phar-

maceutical water system design shall be acquired to minimize

risk,ensure correct quality decisions,and maximize return on

investment (USP Chapter<1231>and (1-7)⁹).TOC measure-

ment technologies are referenced in Test Methods D4839,

D5904,D5997 ,and D6317,and Guide D5173.

9The boldface numbers in parentheses refer to a list of references at the end of

this standard.

3

6.1.2 Technical assessments should be conducted to evalu-

ate and develop a risk-based,science-based RTRT-OLTOC

system design.Knowledge of related information from avail-

able sources should be used to understand,interpret,and

implement the results of the technical assessments.Information

on general and specific RTRT-OLTOC system design

considerations,performance characteristics,and validation can

be found in published documents and texts(8-15).

6.1.3 For existing water purification systems,the user

should assess historical,current,and potential organic contami-

nation.Evaluation of potential organic contamination should

be based on a realistic assessment of water system design and

components to determine the probability of a specific or a

broad spectrum of organic contaminants reaching the water

distribution system.The user should consult with TOC instru-

mentation vendors to determine if the TOC measurement

system will meet the requirements of the intended application

in light of any organic contamination assessment.

6.1.4 For new water purification systems,the presence of

potential problematic compounds in the pharmaceutical water

system shall be addressed during the design and qualification

and validation activities and correction/mitigation/preventive

actions shall be implemented accordingly.

6.1.5 TOC measurement system technology assessments

shall be achieved by meeting regulatory guidance requirements

on analytical procedure verifications and validations

(ICH Q2(R2),USP Chapter<1225>,and U.S.FDA Proce-

dures and Methods Validation).The requirements shall depend

on the use of the data and the intended use of the instrumen-

tation.

6.1.5.1 Legal U.S.Requirements and Verification of

USP Chapter<643>—The use of USP Chapter<643>TOC is

legally recognized to meet the requirements for testing the

TOC attribute in pharmaceutical water.The users of

USP Chapter<643>TOC are not required to validate this

practice,but they shall verify it is suitable under actual

conditions of use.The user shall understand that Section

501(b)of the U.S.Food,Drug,and Cosmetic Act(the Act)

legally recognizes the analytical procedures in the U.S.

Pharmacopeia/National Formulary(USP/NF)for purposes of

determining compliance with this Act(U.S.FDA Procedures

and Methods Validation).The U.S.Federal Regulation CFR

211.194(a)(2)states:the suitability of a compendial analytical

procedure must be verified under actual conditions of use.

Users shall use USP Chapter<1226>,ICH Q2(R2),or equiva-

lent to verify compendial procedures.

6.1.5.2 The procedure for validation and verification of the

TOC analytical method shall depend on the analytical proce-

dure classification in ICH Q2(R2),USP Chapter<1225>,or

the U.S.FDA Procedures and Methods Validation.The mea-

surement of the TOC attribute in water shall be classified as an

impurity test.Under impurity tests are two additional

classifications,quantitative and limit test.For each of these,

there are recommended lists of validation tests to perform.All

pharmacopeia TOC test methods are limit tests.Limit testing

produces only a pass or fail output as graphically represented

by Fig.1.To control,trend,and monitor on-line systems and to

release water in real time using quantitative data,the analytical

method requires the use of quantitative data,so the analytical

method shall be validated to the requirements of quantitative

tests(U.S.FDA PAT Guidance).Quantitative data use is

graphically represented in Fig.2. Classifications and recom-

mended tests are shown in Table 1. Additional helpful infor-

mation can be found in ISO 15839.

6.1.5.3 The U.S.FDA considers "real-time release testing to

be comparable to Alternative Analytical Procedures”and the

U.S.Regulation CFR 211.165 requires that the accuracy,

sensitivity,specificity,and reproducibility of the alternative

analytical test methods or procedures used for process control

purposes be validated and documented.

6.2 Risk Assessment:

6.2.1 If the TOC concentration data is to be used in a

quantitative way for trending,process control,or process

Limit Test for TOC Analysis:

Only allows "Pass"or "Fail"outputs

Fail

500

Pass

0+

Jan-08 Feb-08 Mar-08 Apr-08 May-08 Jun-08 Jul-08 Aug-08 Sep-08 Oct-08 Nov-08 Dec-08

TOC Specification

Pass

FIG.1 “Information Poor”Limit Test Output

Toa

l

Org

ani

c

Car

bon

(pp

b)

摘要:

展开>>

收起<<

ThisinternationalstandardwasdevelopedinaccordancewithinternationallyrecognizedprinciplesonstandardizationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecommendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.Designation:E2656-25I...

声明:如果您的权利被侵害,请联系我们的进行举报。

相关推荐

-

RBA8.0官方中文版VIP免费

2025-11-16 36

2025-11-16 36 -

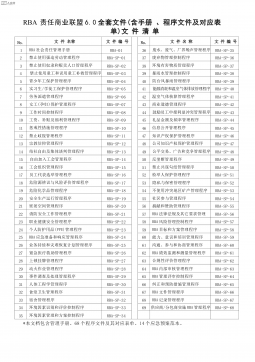

新版RBA责任商业联盟一整套文件(含管理手册、全套程序文件及对应表单)

2025-11-17 40

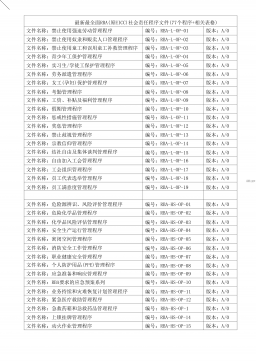

2025-11-17 40 -

最新最全面RBA(原EICC)社会责任程序文件(77个程序+相关表格)

2025-11-17 44

2025-11-17 44 -

RBA-SP-067 供应商分包商实施RBA管理程序

2025-11-18 33

2025-11-18 33 -

RBA-SP-066 记录管理程序

2025-11-18 29

2025-11-18 29 -

RBA-SP-065 文件管理程序

2025-11-18 25

2025-11-18 25 -

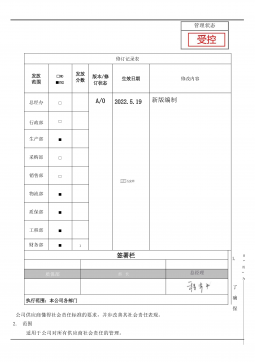

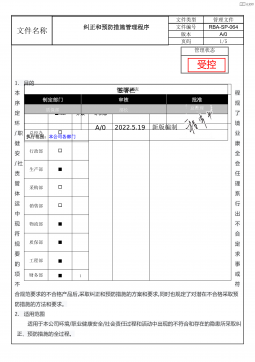

RBA-SP-064 纠正和预防措施管理程序RBA8.0

2025-11-18 26

2025-11-18 26 -

RBA-SP-063 管理评审控制程序

2025-11-18 24

2025-11-18 24 -

RBA-SP-062 内部审核管理程序

2025-11-18 39

2025-11-18 39 -

RBA-SP-006 劳务派遣管理程序

2025-11-18 44

2025-11-18 44

作者: 51zlzl

分类:法规规范

价格:60质量币

属性:8 页

大小:471.36KB

格式:PDF

时间:2025-11-27