ASTM A6-A6M-14_1-16结构用热轧钢棒、板、型钢和钢板桩通用要求标准规范

Designation:A6/A6M-14

Standard Specification for

General Requirements for Rolled Structural Steel Bars,

Plates,Shapes,and Sheet Piling¹

This standard is issued under the fixed designation A6/A6M;the number immediately following the designation indicates the year of

original adoption or,in the case of revision,the year of last revision.A number in parentheses indicates the year of last reapproval.A

superscript epsilon(e)indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S.Deparment of Defense

1.Scope*

1.1 This general requirements specification²covers a group

of common requirements that,unless otherwise specified in the

applicable product specification,apply to rolled structural steel

bars,plates,shapes,and sheet piling covered by each of the

following product specifications issued by ASTM:

Title of Specification

Carbon Structural Steel

Low and Intermediate Tensile Strength Carbon Steel Plates

Steel Sheet Piling

High-Yield Strength,Quenched and Tempered Alloy Steel

Plate Suitable for Welding

High-Strength Carbon-Manganese Steel of Structural Qual-

ity

High-Strength Low-Alloy Columbium-Vanadium Steel

Structural Carbon Steel Plates of Improved Toughness

High-Strength Low-Alloy Structural Steel with 50 ksi(345

MPa)Minimum Yield Point to 4 in.[100 mm]Thick

Normalized High-Strength Low-Alloy Structural Steel Plates

Hot-Rolled Structura SteelHigh-Strength Low-Alloy Plate

with Improved Formability

High-Strength Low-Alloy Steel H-Piles and Sheet Piling for

Use in Marine Environments

Carbon and High-Strength Low-Alloy Structura Steel

Shapes,Plates,and Bars and Quenched-and-Tempered

Alloy Structural Steel Plates for Bridges

Age-Hardening Low-Carbon Nickel-Copper-Chromium-Mo-

lybdenum-Columbium Alloy Structural Steel Plates

Carbon and High-Strength Electric Resistance Welded Steel

Structural Shapes

Rolled Steel Floor Plates

Plates,Carbon Steel,for Forging and Similar Applications

Plates,Alloy Steel,Structural Quality

Plates,Carbon Steel,Structura Quality,Furnished to

Chemical Composition Requirements

Steel Sheet Piling,Cold Formed,Light Gage

High-Strength Low-Alloy Structural Steel Plate With Atmo-

spheric Corrosion Resistance

'This specification is under the jurisdiction of ASTM Commitee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.02 on Structural Steel for Bridges,BuildingsRolling Stock and Ships.

Current edition approved May 1,2014.Published May 2014.Originally

approved in 1949.Last previous edition approved in 2013 as A6/A6M-13a.DOI:

10.1520/A0006_A0006M-14.

²For ASME Boiler and Pressure Vessel Code applications,see related Specifi-

cation SA-6/SA-6M in Section Ⅱ of that Code.

A913/A913M High-Strength Low-Alloy Steel Shapes of Structural Quality,

Produced by Quenching and Self-Tempering Process

(QST)

A871/A871M High-Strength Low-Alloy Structural Steel Plate With Atmo-

spheric Corrosion Resistance

A945/A945M High-Strength Low-Alloy Structural Steel Plate with Low

Carbon and Restricted Sulfur for Improved Weldability,

Formability,and Toughness

A950/A950M Fusion Bonded Epoxy-Coated Structural Steel H-Piles and

Sheet Piling

A992/A992M Steel for Structural Shapes for Use in Building Framing

A1043/A1043M Structural Steel with Low Yield to Tensile Ratio for Use in

Buildings

A1066/A1066M High-Strength Low-Alloy Structural Steel Plate Produced by

Thermo-Mechanical Controlled Process(TMCP)

1.2 Annex A1 lists permitted variations in dimensions and

mass( Note 1)in SI units.The values listed are not exact

conversions of the values in Tables 1 to 31 inclusive but are,

instead,rounded or rationalized values.Conformance to Annex

Al is mandatory when the“M”specification designation is

used.

NoTE 1—The term"weight"is used when inch-pound unts are the

standard;however,under SI,the preferred term is “mass.”

1.3 Annex A2 lists the dimensions of some shape profiles

1.4 Appendix X1 provides information on coil as a source

of structural products.

1.5 Appendix X2 provides information on the variability of

tensile properties in plates and structural shapes.

1.6 Appendix X3 provides information on weldability.

1.7 Appendix X4 provides information on cold bending of

plates,including suggested minimum inside radii for cold

bending.

1.8 This general requirements specification also covers a

group of supplementary requirements that are applicable to

several of the above product specifications as indicated therein.

Such requirements are provided for use where additional

testing or additional restrictions are required by the purchaser,

and apply only where specified individually in the purchase

order.

1.9 In case of any conflict in requirements,the requirements

of the applicable product specification prevail over those of this

general requirements specification.

*A Summary of Changes section appears at the end of this standard

Copynght OASTM International,100 Barr Harbor Drive,PO Box C700,West Conshohocken,PA 19428-2959.United States

Copyright by ASTM Int'l(all rights reserved); 1

A36/A36M

A131/A131M

A242/A242M

A283/A283M

A328/A328M

A514/A514M

A529/A529M

A572/A572M

A573/A573M

A588/A588M

A633/A633M

A656/A656M

A690/A690M

A709/A709M

A710/A710M

A769/A769M

A786/A786M

A827/A827M

A829/A829M

A830/A830M

A857/A857M

A871/A871M

Structura Steel for Ships

High-Strength Low-Alloy Structural Steel

ASTM

Designation³

1.10 Additional requirements that are specified in the pur-

chase order and accepted by the supplier are permitted,

provided that such requirements do not negate any of the

requirements of this general requirements specification or the

applicable product specification.

1.11 For purposes of determining conformance with this

general requirements specification and the applicable product

specification,values are to be rounded to the nearest unit in the

right-hand place of figures used in expressing the limiting

values in accordance with the rounding method of Practice

E29.

1.12 The text of this general requirements specification

contains notes or footnotes,or both,that provide explanatory

material.Such notes and footnotes,excluding those in tables

and figures,do not contain any mandatory requirements.

1.13 The values stated in either inch-pound units or SI units

are to be regarded separately as standard.Within the text,the

SI units are shown in brackets.The values stated in each

system are not exact equivalents;therefore,each system is to

be used independently of the other,without combining values

in any way.

1.14 This general requirements specification and the appli-

cable product specification are expressed in both inch-pound

units and SI units;however,unless the order specifies the

applicable “M”specification designation(SI units),the struc-

tural product is furnished to inch-pound units.

1.15 This standard does not purport to address all of the

safety concerns,if any,associated with its use.It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2.Referenced Documents

2.1 ASTM Standards:³

A131/A131M Specification for Structural Steel for Ships

A370 Test Methods and Definitions for Mechanical Testing

of Steel Products

A673/A673M Specification for Sampling Procedure for Im-

pact Testing of Structural Steel

A700 Practices for Packaging,Marking,and Loading Meth-

ods for Steel Products for Shipment (Withdrawn 2014)⁴

A751Test Methods,Practices,and Terminology for Chemi-

cal Analysis of Steel Products

A829/A829M Specification for Alloy Structural Steel Plates

A941 Terminology Relating to Steel,Stainless Steel,Related

Alloys,and Ferroalloys

E29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

E112 Test Methods for Determining Average Grain Size

E208 Test Method for Conducting Drop-Weight Test to

³For referenced ASTM standards,visit the ASTM website,www.astm.org,or

contact ASTM Customer Service at service@astm.org.For Annual Book of ASTM

Standards volume information,refer to the standard's Document Summary page on

the ASTM website.

⁴The last approved version of this historical standard is referenced on

www.astm.org.

Determine Nil-Ductility Transition Temperature of Fer-

ritic Steels

2.2 American Welding Society Standards:⁵

A5.1/A5.1M Mild Steel Covered Arc-Welding Electrodes

A5.5/A5.5M Low-Alloy Steel Covered Arc-Welding Elec-

trodes

A5.17/A5.17M Specification For Carbon Steel Electrodes

And Fluxes For Submerged Arc Welding

A5.18/A5.18M Specification For Carbon Steel Electrodes

And Rods For Gas Shielded Arc Welding

A5.20/A5.20M Carbon Steel Electrodes For Flux Cored Arc

Welding

A5.23/A5.23M Low Alloy Steel Electrodes And Fluxes For

Submerged Arc Welding

A5.28/A5.28M Specification For Low-Alloy Steel Elec-

trodes And Rods For Gas Shielded Arc Welding

A5.29/A5.29M Specification for Low-Alloy Steel Elec-

trodes for Flux Cored Arc Welding

D1.1/D1.1M Structural Welding Code Steel

2.3 U.S.Military Standards:6

MIL-STD-129 Marking for Shipment and Storage

MIL-STD-163 Steel Mill Products Preparation for Ship-

ment and Storage

2.4 U.S.Federal Standard:6

Fed.Std.No.123 Marking for Shipments(Civil Agencies)

2.5 American Society of Mechanical Engineers Code:?

ASME Boiler and Pressure Vessel Code,Section IX

3.Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 Plates (other than floor plates)—Flat,hot-rolled steel,

ordered to thickness or weight [mass]and typically width and

length,commonly classified as follows:

3.1.1.1 When Ordered to Thickness:

(1)Over 8 in.[200 mm]in width and 0.230 in.[6mm]or

over in thickness.

(2)Over 48 in.[1200 mm]in width and 0.180 in.[4.5 mm]

or over in thickness.

3.1.1.2 When Ordered to Weight [Mass]:

(1)Over 8 in.[200 mm]in width and 9.392 Ib/ft²[47.10

kg/m²]or heavier.

(2)Over 48 in.[1200 mm]in width and 7.3501b/ft²[35.32

kg/m²]or heavier.

3.1.1.3 Discussion—Steel products are available in various

thickness,width,and length combinations depending upon

equipment and processing capabilities of various manufactur-

ers and processors.Historic limitations of a product based upon

dimensions(thickness,width,and length)do not take into

account current production and processing capabilities.To

⁵Available from American Welding Society(AWS),550 NW LeJeune Rd.,

Miami,FL33126,http://www.aws.org.

⁶Available from Standardization Documents Order Desk,DODSSP,Bldg.4,

Section D,700 Robbins Ave.,Philadelphia,PA 19111-5098,http://

www.dodssp.daps.mil.

⁷Available from American Society of Mechanical Engincers(ASME),ASME

International Headquarters,Two Park Ave.,New York,NY 10016-5990,http://

www.asme.org.

Copyright by ASTM Int'l(all rights reserved); 2

Copyright by ASTM Int'(all rights reserved); 3

qualify any product to a particular product specification re-

quires all appropriate and necessary tests be performed and that

the results meet the limits prescribed in that product specifi-

cation.If the necessary tests required by a product specification

cannot be conducted,the product cannot be qualified to that

specification.This general requirement standard contains per-

mitted variations for the commonly available sizes.Permitted

variations for other sizes are subject to agreement between the

customer and the manufacturer or processor,whichever is

applicable.

3.1.1.4 Slabs,sheet bars,and skelp,though frequently

falling in the foregoing size ranges,are not classed as plates.

3.1.1.5 Coils are excluded from qualification to the appli-

cable product specification until they are decoiled,leveled or

straightened,formed (if applicable),cut to length,and,if

required,properly tested by the processor in accordance with

ASTM specification requirements(see Sections 9-15,18,and

19 and the applicable product specification).

3.1.2 Shapes(Flanged Sections):

3.1.2.1 structural-size shapes—rolled flanged sections hav-

ing at least one dimension of the cross section 3 in.[75 mm]or

greater.

3.1.2.2 bar-size shapes—rolled flanged sections having a

maximum dimension of the cross section less than 3 in.[75

mm].

3.1.2.3“W”shapes—doubly-symmetric,wide-flange

shapes with inside flange surfaces that are substantially paral-

lel.

3.1.2.4“HP”shapes—are wide-flange shapes generally

used as bearing piles whose flanges and webs are of the same

nominal thickness and whose depth and width are essentially

the same.

3.1.2.5“S”shapes—doubly-symmetric beam shapes with

inside flange surfaces that have a slope of approximately 162/3

%.

3.1.2.6“M”shapes—doubly-symmetric shapes that cannot

be classified as “W,”"S,"or “HP”shapes.

3.1.2.7“C”shapes—channels with inside flange surfaces

that have a slope of approximately 162/3 %.

3.1.2.8“MC”shapes—channels that cannot be classified as

“C”shapes.

3.1.2.9“L”shapes—shapes having equal-leg and unequal-

leg angles.

3.1.3 sheet piling—rolled steel sections that are capable of

being interlocked,forming a continuous wall when individual

pieces are driven side by side.

3.1.4 bars—rounds,squares,and hexagons,of all sizes;flats

13/64 in.(0.203 in.)and over [over 5 mm]in specified thickness,

not over 6 in.[150 mm]in specified width;and flats 0.230 in.

and over [over 6 mm]in specified thickness,over 6 to 8 in.

[150 to 200 mm]inclusive,in specified width.

3.1.5 exclusive—when used in relation to ranges,as for

ranges of thickness in the tables of permissible variations in

dimensions,is intended to exclude only the greater value of the

range.Thus,a range from 60 to 72 in.[1500 to 1800 mm]

exclusive includes 60 in.[1500 mm],but does not include 72

in.[1800 mm].

3.1.6 rimmed steel—steel containing sufficient oxygen to

give a continuous evolution of carbon monoxide during

soldification,resulting in a case or rim of metal virtually free of

voids.

3.1.7 semi-killed steel—incompletely deoxidized steel con-

taining sufficient oxygen to form enough carbon monoxide

during solidification to offset solidification shrinkage.

3.1.8 capped steel—rimmed steel in which the rimming

action is limited by an early capping operation.Capping is

carried out mechanically by using a heavy metal cap on a

bottle-top mold or chemically by an addition of aluminum or

ferrosilicon to the top of the molten steel in an open-top mold.

3.1.9 killed steel—steel deoxidized,either by addition of

strong deoxidizing agents or by vacuum treatment,to reduce

the oxygen content to such a level that no reaction occurs

between carbon and oxygen during solidification.

3.1.10 mill edge—the normal edge produced by rolling

between horizontal finishing rolls.A mill edge does not

conform to any definite contour.Mill edge plates have two mill

edges and two trimmed edges.

3.1.11 universal mill edge—the normal edge produced by

rolling between horizontal and vertical finishing rolls.Univer-

sal mill plates,sometimes designated UM Plates,have two

universal mill edges and two trimmed edges.

3.1.12 sheared edge—the normal edge produced by shear-

ing.Sheared edge plates are trimmed on all edges.

3.1.13 gas cut edge—the edge produced by gas flame

cutting.

3.1.14 special cut edge—usually the edge produced by gas

flame cutting involving special practices such as pre-heating or

post-heating,or both,in order to minimize stresses,avoid

thermal cracking and reduce the hardness of the gas cut edge.

In special instances,special cut edge is used to designate an

edge produced by machining.

3.1.15 sketch—when used to describe a form of plate,

denotes a plate other than rectangular,circular,or semi-

circular.

3.1.16 normalizing—a heat treating process in which a steel

plate is reheated to a uniform temperature above the upper

critical temperature and then cooled in air to below the

transformation range.

3.1.17 plate-as-rolled—when used in relation to the location

and number of tests,the term refers to the unit plate rolled from

a slab or directly from an ingot.It does not refer to the

condition of the plate.

3.1.18 fine grain practice—a steelmaking practice that is

intended to produce a killed steel that is capable of meeting the

requirements for fine austenitic grain size.

3.1.18.1 Discussion—It normally involves the addition of

one or more austenitic grain refining elements in amounts that

have been established by the steel producer as being sufficient.

Austenitic grain refining elements include,but are not limited

to,aluminum,columbium,titanium,and vanadium.

3.1.19 structural product—a hot-rolled steel plate,shape,

sheet piling,or bar.

摘要:

展开>>

收起<<

Designation:A6/A6M-14StandardSpecificationforGeneralRequirementsforRolledStructuralSteelBars,Plates,Shapes,andSheetPiling¹ThisstandardisissuedunderthefixeddesignationA6/A6M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumb...

声明:如果您的权利被侵害,请联系我们的进行举报。

相关推荐

-

RBA8.0官方中文版VIP免费

2025-11-16 36

2025-11-16 36 -

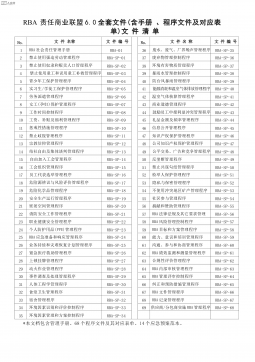

新版RBA责任商业联盟一整套文件(含管理手册、全套程序文件及对应表单)

2025-11-17 40

2025-11-17 40 -

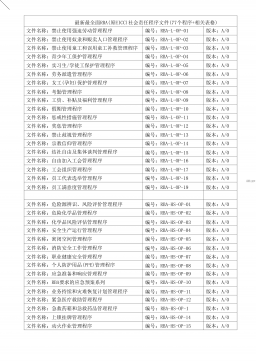

最新最全面RBA(原EICC)社会责任程序文件(77个程序+相关表格)

2025-11-17 44

2025-11-17 44 -

RBA-SP-067 供应商分包商实施RBA管理程序

2025-11-18 33

2025-11-18 33 -

RBA-SP-066 记录管理程序

2025-11-18 29

2025-11-18 29 -

RBA-SP-065 文件管理程序

2025-11-18 25

2025-11-18 25 -

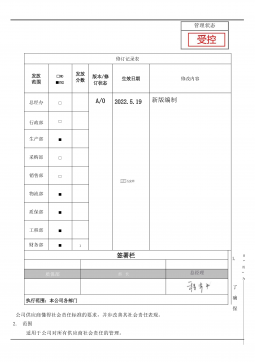

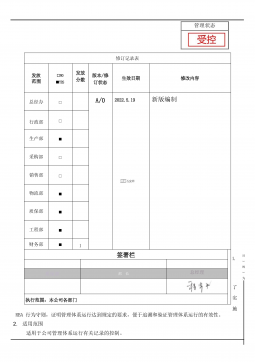

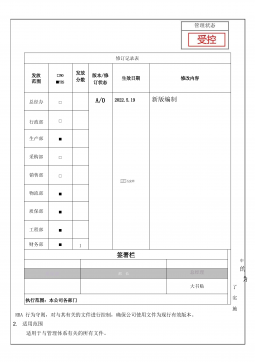

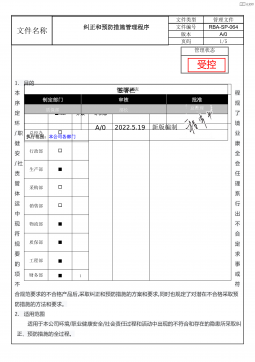

RBA-SP-064 纠正和预防措施管理程序RBA8.0

2025-11-18 26

2025-11-18 26 -

RBA-SP-063 管理评审控制程序

2025-11-18 24

2025-11-18 24 -

RBA-SP-062 内部审核管理程序

2025-11-18 39

2025-11-18 39 -

RBA-SP-006 劳务派遣管理程序

2025-11-18 44

2025-11-18 44

作者:冒牌货

分类:法规规范

价格:200质量币

属性:63 页

大小:1.86MB

格式:PDF

时间:2025-12-12