ASTM F1877-24 Characterization of Particles

VIP免费

1

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards,Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade(TBT)Committee.

Designation:F1877-24

INTERNATIONAL

Standard Practice for

Characterization of Particles¹

This standard is issued under the fixed designation F1877;the number immediately following the designation indicates the year of

original adoption or,in the case of revision,the year of last revision.A number in parentheses indicates the year of last reapproval.A

superscript epsilon(e)indicates an editorial change since thelast revision or reapproval.

1.Scope

1.1 This practice covers a series of recommendations,gen-

erally applicable to all medical devices,for characterization of

the morphology,shape,size,and size distribution of particles.

The methods utilized include sieves,optical,scanning electron

microscopy(SEM),transmission electron microscopy(TEM),

and electrooptical.

1.2 While characterizing the quantity or number of particles

shed from medical devices is important,this is not covered

within the scope of the current document.AAMI TIR 42 and

USP<788>provide guidelines for determination of particle

quantities in various size ranges.

1.3 These methods are appropriate for particles produced by

a number of different methods.These methods can include

simulated use approaches such as in vitro wear test machines

(Test Method F732),total joint simulation systems(Guides

F1714 and F1715),abrasion testing,and vascular durability

testing(Guide F2942).Other methods for producing particles

such as shatter boxes or pulverizers,as well as commercially

available particles,and particles harvested from tissues in

animal or clinical studies can be used.

1.4 Except for chemical composition,this standard does not

address sample preparation procedures and/or test systems that

can be affected by chemical properties(for example,solubility,

miscibility).While this standard does not provide detailed

recommendations regarding assessment of chemical properties

of particles,these should be considered.

1.5 The particles may be metallic,polymeric,or ceramic

and are released from medical device materials either acutely

or chronically(for example,due to wear).

1.6 The digestion procedures to be used and issues of

sterilization of retrieved particles are not the subject of this

practice.

1.7 A classification scheme for description of particle mor-

phology is included in Appendix X3.

!This practice is under the jurisdiction of ASTM Committe F04 on Medical and

Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.16 on Biocompatibility Test Methods.

Current edition approved Oct.1,2024.Published October 2024.Originally

approved in 1998.Last previous edition approved n 2016 as F1877-16.DOI:

10.1520/F1877-24.

1.8 When nanoparticles (that is,having at least one dimen-

sion less than 100 nm)are known to be present or are expected,

other characterization methods may be needed.For informa-

tion regarding nanoparticle characterization,refer to standards

that address nanoparticles(for example,ISO 21363,ISO/TR

10993-22,ISO/TR 16196).

1.9 This standard does not address ions released from

medical devices.

1.10 The values stated in SI units,including units officially

accepted for use with SI,are to be regarded as standard.No

other systems of measurement are included in this standard.

1.11 As a precautionary safety measure for handling test

samples during particle characterization analyses,removed

particles from implant tissues should be sterilized or minimally

disinfected by an appropriate means that does not adversely

affect these particles.

1.12 This standard does not purport to address all of the

safety concerns,if any,associated with its use.It is the

responsibility of the user of this standard to establish appro-

priate safety,health,and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

1.13 This international standard was developed in accor-

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

Development of International Standards,Guides and Recom-

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT)Committee.

2.Referenced Documents

2.1 ASTM Standards:²

C678 Test Method for Determination of Particle Size Distri-

bution of Alumina or Quartz Using Centrifugal Sedimen-

tation (Withdrawn 1995)³

E11 Specification for Woven Wire Test Sieve Cloth and Test

Sieves

E161 Specification for Electroformed Material and Test

Sieves

²For referenced ASTM standards,visit the ASTM website,www.astm.org,or

contact ASTM Customer Service at www.astm.org/contact.For Annual Book of

ASTM Standards volume information,refer to the standard's Document Summary

page on the ASTM website.

3The last approved version of this historical standard is referenced on

www.astm.org.

Copyright ◎ASTM Intermational,100 Barr Harbor Drive,PO Box C700,West Conshohocken,PA 19428-2959.United States

2

F1877-24

E766 Practice for Calibrating the Magnification of a Scan-

ning Electron Microscope

E1617 Practice for Reporting Particle Size Characterization

Data

F561 Practice for Retrieval and Analysis of Medical

Devices,and Associated Tissues and Fluids

F660 Practice for Comparing Particle Size in the Use of

Alternative Types of Particle Counters

F661 Practice for Particle Count and Size Distribution Mea-

surement in Batch Samples for Filter Evaluation Using an

Optical Particle Counter (Withdrawn 2000)³

F662 Test Method for Measurement of Particle Count and

Size Distribution in Batch Samples for Filter Evaluation

Using an Electrical Resistance Particle Counter (With-

drawn 2002)³

F732 Test Method for Wear Testing of Polymeric Materials

Used in Total Joint Prostheses

F1714 Guide for Gravimetric Wear Assessment of Prosthetic

Hip Designs in Simulator Devices

F1715 Guide for Wear Assessment of Prosthetic Knee De-

signs in Simulator Devices (Withdrawn 2006)³

F2942 Guide for in vitro Axial,Bending,and Torsional

Durability Testing of Vascular Stents

2.2 ISO Standards:⁴

ISO 21363 Nanotechnologies—Measurements of particle

size and shape distributions by Transmission Electron

Microscopy

ISO 13322-1 Particle size analysis—Image analysis

methods—Part 1:Static image analysis methods

ISO/TR 10993-22 Biological evaluation of medical

devices—Part 22:Guidance on nanomaterials

ISO/TR 16196 Nanotechnologies—Compilation and de-

scription of sample preparation and dosing methods for

engineered and manufactured nanomaterials

2.3 AAMI Document:⁵

AAMI TIR 42:2021 Evaluation of Particulate Associated

with Vascular Medical Devices

2.4 U.S.Pharmacopeia:⁶

USP<788> Particulate Matter in Injections⁷

3.Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 agglomerate,n—a jumbled mass or collection of two

or more particles or aggregates,or a combination thereof,held

together by relatively weak cohesive forces caused by weak

chemical bonding or an electrostatic surface charge generated

by handling or processing.

4Available from American National Standards Institute(ANSD),1180 Avenue of

the Americas,10th Floor,New York,NY 10036,http://www.ansi.org.

5Available from Association for the Advancement of Medical Instrumentation

(AAMI),4301 N.Fairfax Dr.,Suite 301,Arlington,VA 22203-1633,http://

www.aami.org.

⁶Available from U.SPharmacopeial Convention(USP),12601 Twinbrook

Pkwy.,Rockville,MD 20852-1790,http://www.usp.org.

7USP<788>is intended to provide recommendations for particulate evaluations

of injections and parenteral infusions,and is generally not applicable to medical

devices.While limitations of this standard exist and the method used should be

validated,it provides some useful information(for example,particle quantification

methods,system cleanliness recommendations)

3.1.2 aggregate,n—a dense mass of particles held together

by strong intermolecular or atomic cohesive forces that is

stable with normal mixing techniques,including high-speed

stirring and ultrasonics.

3.1.3 aspect ratio (AR),n—a ratio of the major to the minor

Feret diameters of a particle(see 12.3.3).

3.1.4 elongation(E),n—ratio of the particle length to the

average particle width(see 12.3.4).

3.1.5 equivalent circle diameter(ECD),n—the diameter of

a circle with an area equivalent to the area of the particle (see

12.3.2 and Appendix X1).

3.1.6 Feret diameter;n—the mean value of the distance

between pairs of parallel tangents to a projected outline of a

particle.

3.1.7 form factor(FF),n—a dimensionless number relating

area and perimeter of a particle,as determined in 12.3.6.

3.1.8 irregular;,adj—referring to a particle that cannot be

described as round or spherical.A set of standard nomenclature

and reference figures are given in Appendix X2.

3.1.9 matrix,n—particle-free sample that represents the

starting composition of test samples prior to preparation (for

example,digestion/harvest)or analysis.

3.1.10 method qualification,n—the process of evaluating

the accuracy,precision,and bias of sample preparation and

particle characterization analyses of test particle suspensions

based on comparison with defined samples of particles with

similar properties.The purpose is to qualify the acceptability of

the analytical outcomes.

3.1.11 morphology,n—referring to size,shape,structure,

and texture.

3.1.12 particle,n—the smallest discrete unit detectable as

determined in test methods.

3.1.13 particle breadth,n—distance between touch points of

the shortest Feret pair,orthogonal to length.

3.1.14 particle length,n—distance between the touch points

of maximum Feret pair.This value will be greater than or equal

to the maximum Feret diameter.

3.1.15 reference particles,n—particle samples with defined

properties(for example,size,shape,composition,density,

population distribution,agglomeration)that are used for

method qualification.

3.1.16 rectangular;adj—referring to a particle that approxi-

mates a square or rectangle in shape.

3.1.17 roundness(R),n—a measure of how closely an

object represents a circle as determined in 12.3.5.

3.1.18 spherical,adj—referring to a particle that approxi-

mates a sphere in a three-dimensional space and that projects as

a round (or circular)shape in a two-dimensional space.A

sphere is a three-dimensional,geometrical shape that has all its

surface points equidistant from a common point.

3.1.19 spiked matrix,n—matrix with reference particles

added at known concentration(s).

3

F1877-24

much as possible.When there is uncertainty regarding the

characteristics of particles produced from in vitro or bench

testing,particles from clinical studies(for example,retrievals)

can be used to enhance the clinical representativeness of testing

and its predictive power for characterizing potential biological

responses.

6.Interferences

6.1 Particles may form aggregates or agglomerates during

preparation and storage.These could result in an increase in

measured particle size.It is essential that care be taken to

resuspend particles prior to analysis and to note any effects of

the dispersant used.Details regarding resuspension of particles

prior to analysis are provided in AAMI TIR 42.

6.2 Particles from wear tests or harvested from tissues may

contain a mixture of materials.In order to determine all

potential sources of particle generation,appropriate methods

should be utilized to determine the chemical composition of the

entire particulate sample.Care should be taken when separat-

ing the particles and analyzing the physical characteristics and

chemical composition of the isolated particles.

6.3 Many automated particle counters operate on the as-

sumption that the particles are spherical.These methods may

not be appropriate for nonspherical debris.Additional methods

should be used to verify size,shape,and quantity using

methods that take aspect ratio into consideration,for example,

SEM or TEM image analysis.

7.Apparatus

7.1 Scanning Electron Microscope(SEM)(see Practice

E766,ISO 19749):

7.1.1 Standard SEM equipment can be utilized for many

studies.In special instances,such as with polymeric particles,

a low acceleration voltage(1 to 2 kV)machine with a high

brightness electron source,such as a field emission tip,may be

utilized.

7.1.2 Elemental analysis may be accomplished with an

energy dispersive X-ray spectrometer(EDS)with SEM.

7.1.3 Fourier transform infrared spectroscopy(FTIR)and

Raman spectroscopy are robust analytical methods to identify

the chemical composition(that is,chemical compounds pres-

ent)of bulk or individual particles.

7.2 Transmission Electron Microscopy (TEM):

7.2.1 TEM equipment can be typically used for the analysis

of nanoparticles,although SEM with a field emission tip has

also been successfully used to characterize particles as small as

50 to 100 nm.

7.2.2 Elemental analysis may be accomplished with an

energy dispersive X-ray spectrometer(EDS)coupled with

TEM.

7.3 Optical Microscope—An optical microscope operating

in the transmission mode may be utilized.Dark field illumina-

tion may enhance visualization of some particles.Polarized

light will facilitate identification of semicrystalline polymeric

materials.

7.4 Automatic Particle Counters(see Practice F660):

4.1 When evaluating particles generated from medical

devices,the final device within their designated commercial

packaging,including sterilization as applicable,should be used

in all evaluations.

4.2 Particles produced by implant wear in vivo in animal or

clinical studies are harvested from tissues after digestion

utilizing methods such as those in Practice F561.

4.3 Particles generated in vitro or obtained from commercial

sources are used as received,or after digestion if they were

generated in protein solutions,and further separation if there

are signs of aggregation.Harvesting and further processing

should maintain the original range and physical and chemical

characteristics of particles from in vivo or in vitro studies.For

routine analysis,the particles are characterized by the terms of

morphology and by size using Feret diameters and equivalent

circle diameter(ECD).For more detailed studies,several

methods that may be utilized for numerically characterizing

their dimensions and size distribution are described.

5.Significance and Use

5.1 The biological response to materials in the form of small

particles,as produced from implant wear,abrasion,or erosion,

often is significantly different from that to the same materials

in bulk form (that is,an implant component).Additionally,the

morphology(for example,size and shape,surface

characteristics),volume distribution,and species of these

particles are major determinants of device-related biological

responses;therefore,this practice provides standardized no-

menclature for describing particles.Such a unified nomencla-

ture will be of value in interpretation of biological tests of

responses to particles,in that it will facilitate separation of

biological responses per different particle characteristics such

as size,shape,and volume.

5.2 Particles released due to wear from implants in vivo may

result in an adverse biological response which will affect the

long-term survival of the device.Characterization of such

particles will provide valuable information regarding the safety

and effectiveness of device designs or methods of processing

components and the mechanisms of wear.

5.3 The morphology of particles produced in laboratory

tests of wear and abrasion often is affected by the test

conditions,such as the magnitude and rate of load application,

device configuration,and test environment.Comparison of the

morphology,size,and quantity of particles produced in vitro

with those produced in vivo will provide valuable information

regarding the degree to which the method simulates the in vivo

condition being modeled.

5.4 Particles harvested from particle-release studies(for

example,cell culture experiments,third body wear simulation)

that are to be used for testing should be representative of the

entire spectrum of possible particles produced from clinical use

of the device/material under review(for example,due to wear,

abrasion,or erosion).Therefore,efforts should be made to

ensure that the particles for testing were produced from in vivo

/in vitro studies that mimicked the clinical use conditions as

4.Summary of Practice

摘要:

展开>>

收起<<

1ThisinternationalstandardwasdevelopedinaccordancewithinternationallyrecognizedprinciplesonstandardizationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecommendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.Designation:F1877-24...

声明:如果您的权利被侵害,请联系我们的进行举报。

相关推荐

-

ASTM F3172-15 血管内医疗器械设计验证数量和样本容量选择指南

2024-04-15 138

2024-04-15 138 -

ASTM-D-882-测量塑料薄膜和薄片材拉伸性能(

2024-04-16 103

2024-04-16 103 -

ASTM F838-2015 确定用于液体过滤的膜过滤器的细菌滞留的标准试验方法

2024-05-09 98

2024-05-09 98 -

ASTM F3064-21 Standard Specification for Normal Category Aeroplanes CertificationVIP免费

2024-05-09 58

2024-05-09 58 -

ASTM D3195 D3195M-10(2015) Standard Practice for Rotameter CalibrationVIP免费

2024-05-09 66

2024-05-09 66 -

ASTM D4169-22 运输集装箱和系统的性能测试1(中文版)VIP免费

2025-09-09 56

2025-09-09 56 -

ASTM D4169 运输集装箱和设备性能试验的标准实施规范(中英文)VIP免费

2025-09-09 42

2025-09-09 42 -

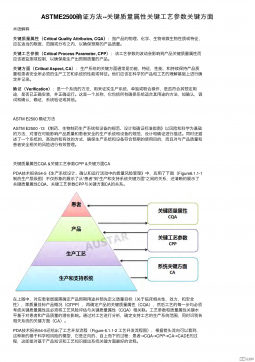

ASTME2500 确证方法--关键质量属性关键工艺参数关键方面VIP免费

2025-09-26 26

2025-09-26 26 -

ASTM E2500-25 药品的规格、设计与验证以及生物制药生产系统装备科学与基于风险的方法1(中文)VIP免费

2025-11-21 86

2025-11-21 86 -

ASTM E3219-25 基于健康的暴露限值(HBEL)推导指南(中文)

2025-12-17 82

2025-12-17 82

作者:冒牌货

分类:法规规范

价格:100质量币

属性:16 页

大小:1.12MB

格式:PDF

时间:2026-01-05