PDA-TR49-生物清洁验证-中英文翻译

Page 1 of 95

Points to Consider

for

Biotechnology

Cleaning

V

alidation

Technical Report No.

49

ISBN: 978-0-939459-30-8

©

2010 Parenteral Drug Association,

Inc.

All rights

reserved.

Page 2 of 95

Table of Contents

1.0

I

NTR

odu

CTI

o

N

..................................................3

1.1

Purpose/Scope

...............................................

3

2.0

Gl

ossa

R

y

oF

Te

R

ms

........................................5

3.0

CleaNING PRoCess

desIGN

aNd

deVeloPmeNT

..........................................6

3.1

Introduction ....................................................

6

3.2

Cleaning Process Controls

(Inputs)

and Measurements (Outputs)

.........................

6

3.2.1

Cleaning Cycle Design ........................

6

3.2.2

Physical-Chemical Aspects ................

7

3.3

Measurements Used to

Determine

Cleaning

Effectiveness....................................

8

3.4

Equipment and Plant

Design Considerations

....................................

8

3.4.1

Piping..................................................

8

3.4.2

Automated vs. Manual Systems.........

9

3.4.3

Centralized CIP vs.

Discrete

Cleaning of Isolated Equipment...........

9

3.4.4

Clean Out of Place (COP)

....................

9

3.5

Soil Evaluation and

Categorization

..................

9

3.5.1

Soil Categories....................................

9

3.5.2

Soil

R

emoval

.....................................

10

3.5.3

Cleaning

Comparability

Based on Soil and

Surface

................

11

3.5.4

Soil Selection

for

Laboratory Evaluations .....................

12

3.6

Performing Cleaning

Development Experiments

............................

12

3.6.1

Parameter Selection..........................

13

3.6.2

Parameter Interactions......................

13

3.7

Cleaning Process Scale-Up

...........................

13

3.7.1

Setting Process Controls...................

14

3.7.2

Introduction of New

Soils

to a Validated Cleaning System ........

14

3.8

Applying the “Design

Space”

Concept to Cleaning Processes ....................

15

4.

0

aCC

e

PT

a

NC

e

lI

m

IT

s

.......................................17

4.1

Key Issues in Limits for

Actives

....................

17

4.1.1

Establishing Limits for Actives

in

Formulation and Final Fill

..................

18

4.1.2

Establishing Limits

for

Actives in Bulk Manufacture.............

18

4.1.3

Limits Based on Toxicity Data...........

19

4.2

Limits for Cleaning

Agents............................

20

4.2.1

Limits for Commodity

Chemicals

......

20

4.2.2

Limits for

Formulated

Cleaning

Agents................................

20

Page 3 of 95

4.3

Bioburden Limits...........................................

21

4.4

Endotoxin

Limits

...........................................

21

4.5

Visual Clean

Criterion....................................

21

4.6

Modifying

Limits

...........................................

22

5.0

s

am

P

l

ING

m

e

T

hods

......................................23

5.1

Sampling Method Selection..........................

23

5.1.1

Direct Sampling Methods .................

23

5.1.2

Rinse

Sampling

.................................

23

5.1.3

Swab Sampling.................................

24

5.1.4

Comparison of

Swab

and Rinse

Sampling

..........................

25

5.2

Placebo

Sampling

.........................................

26

5.3

Sampling for

Microbial

and Endotoxin Analysis.................................

26

5.4

Sampling Recovery Studies

..........................

26

5.4.1

General

Considerations

.....................

26

5.4.2

Swab Recovery.................................

27

5.4.3

Rinse Recovery ................................

27

5.4.4

“R

ecovery

”

in Visual Inspection........

28

5.4.5

Recovery for

Bioburden

and Endotoxin Sampling ...................

28

5.5

Training and Qualification of Samplers

..........

29

5.5.1

Key Issues for

T

raining

for Swab Sampling ...........................

29

5.5.2

Key Issues for

T

raining

for Rinse Sampling............................

30

5.5.3

Training for Visual Inspection

............

30

6.0 aN

al

y

TIC

al

m

e

T

hods

...................................31

6.1

Specific Analytical Methods

.........................

31

6.2

Impact of

Inactivation/Degradation

of the

Active

.................................................

31

6.3

Nonspecific Analytical Methods

...................

32

6.3.1

Total Organic Carbon (TOC)...............

32

6.3.2

Total

P

rotein

......................................

33

6.3.3

Conductivity......................................

33

6.3.4

Visual Inspection...............................

34

6.4

Microbial Test

Methods

................................

35

6.4.1

Endotoxin..........................................

35

6.4.2

Bioburden .........................................

35

6.5

Analytical Method Validation ........................

35

6.5.1

General

P

rinciples

.............................

36

6.5.2

Compendia

Methods.........................

37

6.5.3

Visual Inspection...............................

37

6.5.4

Bioburden Methods ..........................

37

6.5.5

Use of a Contract Laboratory

............

37

7.0

CleaNING

V

al

Id

a

TI

o

N

PRoToCols

..............39

7.1

Cleaning Verification Protocols......................

39

摘要:

展开>>

收起<<

Page1of95PointstoConsiderforBiotechnologyCleaningValidationTechnicalReportNo.49ISBN:978-0-939459-30-8©2010ParenteralDrugAssociation,Inc.Allrightsreserved.Page2of95TableofContents1.0INTRoduCTIoN..................................................31.1Purpose/Scope...........................................

声明:如果您的权利被侵害,请联系我们的进行举报。

相关推荐

-

医疗器械经营质量管理规范(2023年)

2024-04-11 119

2024-04-11 119 -

医疗器械可用性工程注册审查指导原则

2024-04-15 100

2024-04-15 100 -

中文版+IVDR+EU2017-746欧盟医疗器械新法规

2024-05-02 537

2024-05-02 537 -

IVDR-2017-746

2024-05-02 80

2024-05-02 80 -

医疗器械管理法与医疗器械监督管理条例对比

2024-09-04 65

2024-09-04 65 -

CAR-T细胞制剂制备质量管理规范VIP免费

2025-06-08 74

2025-06-08 74 -

IVDR EU 2017-746 体外诊断医疗器械法规(中文版)VIP免费

2025-09-02 44

2025-09-02 44 -

CNCA-QMS-01:2025 质量管理体系认证规则VIP免费

2025-10-24 126

2025-10-24 126 -

医疗器械生产质量管理规范

2025-11-04 77

2025-11-04 77 -

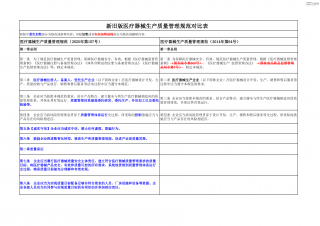

《医疗器械生产质量管理规范》新(2025)旧(2014)对比表VIP免费

2025-11-05 411

2025-11-05 411

作者:薛定谔的龙猫

分类:专业资料

价格:120质量币

属性:95 页

大小:2.1MB

格式:PDF

时间:2025-11-19