ASTM E2500-25_药品的规格、设计与验证以及生物制药生产系统装备科学与基于风险的方法1(中英文)

VIP专享

This internatio

nal standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Developm

ent of International Standards,Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade(TBT)Committee.

Designation:E2500-25

INTERATIONAL

Standard Guide for

Specification,Design,and Verification of Pharmaceutical

and Biopharmaceutical Manufacturing Systems and

Equipment Science and Risk Based Approach¹

This standard is issued under the fixed designation E2500;the number immediately following the designation indicates the year of

original adoption or,in the case of revision,the year of last revision.A number in parentheses indicates the year of last reapproval.A

superscript epsilon(e)indicates an editorial change since the last revision or reapproval

1.Scope

1.1 This guide is applicable to all elements of pharmaceu-

tical and biopharmaceutical manufacturing systems including:

good manufacturing practice(GMP)utility equipment,process

equipment,supporting utilities,associated process monitoring

and control systems,and automation systems that have the

potential to affect product quality,availability,and/or patient

safety.

1.2 For brevity,these are referred to throughout the rest of

this guide as manufacturing systems.

1.3 This guide may also be applied to laboratory,medical

device manufacturing systems (laboratory instrument qualifi-

cation is covered in USP<1058>),and information(software

qualification is covered by ISPE GAMP Series documents;risk

management of medical device manufacturing is covered in

ISO 14971).

1.4 This guide is applicable to both new and existing

manufacturing systems.The approach may be used for imple-

mentation of changes to existing systems.

1.5 This guide is applicable throughout the life cycle of the

manufacturing system from concept to retirement.

1.6 The impact of quality risk management for an entire

facility(such as contamination control strategy(CCS))is not a

part of the scope and subject to separate assessments;however,

the outputs from these exercises could serve as inputs to the

process risks and/or risk mitigations that may be subsequently

used in assessments of manufacturing systems.

1.7 This standard does not address employee health and

safety,environmental,or other non-GxP regulations.This

standard does not purport to address all ofthe safety concerns,

ifany,associated with its use.It is the responsibility of the user

of this standard to establish appropriate safety,health,and

environmental practices and determine the applicability of

regulatory limitations prior to use.

1.8 This international standard was developed in accor-

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

Development of International Standards,Guides and Recom-

mendations issued by the World Trade Organization Technical

Barriers to Trade(TBT)Committee.

2.Referenced Documents

2.1 ASTM Standards:²

E2363 Terminology Relating to Manufacturing of Pharma-

ceutical and Biopharmaceutical Products in the Pharma-

ceutical and Biopharmaceutical Industry

E2474 Practice for Pharmaceutical Process Design Utilizing

Process Analytical Technology (Withdrawn 2020)³

E2476 Guide for Risk Assessment and Risk Control as it

Impacts the Design,Development,and Operation of PAT

Processes for Pharmaceutical Manufacture

E2537 Guide for Application of Continuous Process Verifi-

cation to Pharmaceutical and Biopharmaceutical Manu-

facturing

E2629 Guide for Verification of Process Analytical Technol-

ogy(PAT)Enabled Control Systems

E3051 Guide for Specification,Design,Verification,and

Application of Single-Use Systems in Pharmaceutical and

Biopharmaceutical Manufacturing

2.2 FDA Documents:⁴

EU GMPAnnex 11 Computerized Systems

EU GMP Annex 15 Qualification and Validation

FDA Guidance for Industry Process Validation General Prin-

ciples and Practices

IThis guide is under the jurisdiction of ASTM Committee E55 on Manufacture

of Pharmaceutical and Biopharmaceutical Products and is the direct responsibility of

Subcommittee E55.11 on Process Design.

Current edition approved March 15,2025.Published April 2025.Originally

approved in 2007.Last previous edition approved in 2020 as E2500-20.DOI:

10.1520/E2500-25.

²For referenced ASTM standards,visit the ASTM website,www.astm.org,or

contact ASTM Customer Service at www.astm.org/contact.For Annual Book of

ASTM Standards volume information,refer to the standard's Document Summary

page on the ASTM website.

³The last approved version of this historical standard is referenced on

www.astm.org.

4Available from Food and Drug Administration(FDA),5600 Fishers Ln.,

Rockville,MD 20857,http://www.fda.gov.

Copyright OASTM International,100 Barr Harbor Drive,PO Box C700,West Conshohocken,PA 19428-2959.United States

工

本国际标准是根据世界贸易组织技术性贸易壁垒委员会(TBT)发布的《关于制定国际标准、指南和建议的原则的决定》中确立的国际公认标准化原则制定的。

Designation:E2500-25

INTERATIONAL

标准指南

药品的规格、设计与验证

以及生物制药生产系统

装备科学与基于风险的方法1

本标准采用固定编号E2500发布;紧随编号后的数字表示发布年份。

原始采纳年份,或在修订情况下,末次修订年份。括号内数字表示末次重新批准年份。

上标ε(e)表示自上次修订或重新批准以来的编辑变更

1. 范围

1.1 本指南适用于制药和生物制药生产系统的所有要

素,包括:药品生产质量管理规范(GMP)公用设备、工

艺设备、辅助公用设备、相关工艺监控和控制系统以及可

能影响产品质量、可用性和/或患者安全的自动化系统。

1.2 出于简洁考虑,

本指南中将这些称为制造系统。

1.3 本指南也可适用于实验室、医疗器械制造系统(实

验室仪器确认涵盖在USP中<1058>),以及信息(软件确

认涵盖在 ISPE GAMP系列文件中;医疗器械制造的风险管

理涵盖在ISO 14971中)。

1.4 本指南适用于新建和现有制造系统。该方法可用于

现有系统的变更实施。

1.5 本指南适用于制造系统的整个生命周期,从概念设计直至退

役。

1.6 整个设施(如污染控制策略(中国化学会))的质

量风险管理影响不属于评估范围,需进行单独评估;然

而,这些评估的输出结果可作为工艺风险和/或风险缓解措

施的输入,这些措施可能随后用于制造系统的评估。

1.7

本标准不涉及员工健康安全、环境或其他非

GxP

(通用良好规范)法规。本标准不声称涵盖其使用过程中

可能存在的所有安全问题(如有)。用户有责任建立适当

的安全、健康及

在使用前评估环境实践并确定监管限制的适用性。

1.8

本国际标准是根据世界贸易组织技术性贸易壁垒

(

TBT

)委员会发布的《关于制定国际标准、指南和建议

的原则的决定》中确立的国际公认标准化原则制定的。

2. 参考文献

2.1 ASTM

标准:

²

E2363制药和生物制药产品生产相关的术语

非洲和生物制药行业E2474利用

过程分析技术(2020年撤回)³

E2476风险评估和风险控制指南

影响PAT的设计、开发和运营

药品生产过程

E2537药品和生物制品连续工艺验证应用指南

开票

E2629工艺分析技术(PAT)控制系统的验证指南

E3051规范、设计、验证和

一次性使用系统在制药领域的应用

生物制药生产

2.2 FDA

文件: ⁴

EU GMP附录11计算机系统

EU GMP 附件15 资质与确认

FDA行业工艺验证指南一般原则和实践

本指南由ASTM委员会E55药品和生物制品生产管辖,由工艺设计分委员会E

55.11直接负责。

现行版本于2025年3月15日批准,2025年4月发布。最初于2007年批准,上

一版本于2020年作为E2500-20批准。DOI:10.1520/E2500-25 。

www.astm.org²For 如需参考ASTM标准,请访问ASTM 网 站 ,或 联系 AS-

TM客户服务部,电话: www.astm.org/contact 。如需了解《ASTM标准年鉴》

卷信息,请访问ASTM网站上的标准文件摘要页面。

³The 该历史标准的最后批准版本可参考www.astm.org。

4可从美国食品药品监督管理局(FDA)获得,地址:5600 Fishers Ln.,Rockville,MD

20857,http://www.fda.gov。

版权 所 有 OASTM International,100 Barr Harbor Drive,PO Box C700,West Conshohocken,PA 19428-2959. United

States工

FDA Guidance Part 11 Electronic Records;Electronic Sig-

natures —Scope and Application

FDA Pharmaceutical cGMPs for the 21st Century —A

Risk-Based Approach

2.3 ICH Documents:⁵

ICH Q7 Active Pharmaceutical Ingredients

ICH Q8(R2) Pharmaceutical Development

ICH Q9(R1)Quality Risk Management

ICH Q10 Pharmaceutical Quality System

ICHQ11 Development and Manufacture of Drug Substances

(Chemical Entities and Biotechnological/Biological Enti-

ties)

ICHQ12 Technical and Regulatory Considerations for Phar-

maceutical Product Lifecycle Management —Scientific

Guideline

ICH Q13 Continuous Manufacturing of Drug Substances

and Drug Products Guidance for Industry

2.4 Other Publications:

ISPE Baseline 5 Guide for Commissioning and Qualifica-

tion Second Edition⁶

ISPE Good Practice Guide(GPG)for Good Engineering

Practice(GEP) Second Edition⁶

USP<1058> Analytical Instrument Qualification and its

Impact on the Chromatography Laboratory⁷

ISO 14971 Risk Management⁸

3.Terminology

3.1 Definitions—For definitions of terms used in this guide,

refer to Terminology E2363.

3.1.1 acceptance criteria,n—numerical limits,ranges,or

other suitable measures for acceptance of test results(ICH Q7).

The criteria that a system or component must meet in order to

be accepted by a user or other authorized entity.

3.1.2 commissioning,n—a planned,managed and docu-

mented approach to the setting to work,start-up,regulation and

adjustment,and installation/operation/performance verification

necessary to bring equipment,automation and systems to a

fully operational state meeting safety and end-user require-

ments.

3.1.3 critical aspects of manufacturing systems,n—are typi-

cally functions,features,abilities,and performance or charac-

teristics necessary for the manufacturing process and systems

to ensure that critical process parameters are consistently

controlled,and other requirements are met(for example,

regulatory requirements).They should be identified and docu-

mented based on scientific product and process understanding.

3.1.3.1 Discussion—For brevity,critical aspects of manu-

5 Available from International Conference on Harmonisation of Technical

Requirements for Registration of Pharmaceuticals for Human Use(ICH),ICH

Secretariat,9,chemin des Mines,P.O.Box 195,1211 Geneva 20,Switzerland,

http://www.ich.org.

⁶Available from International Society for Pharmaceutical Engineering(ISPE),

3001 N Rocky Point Dr.East,Suite 200,Tampa,FL33607,http://www.ispe.org.

⁷Available from U.S.Pharmacopeial Convention(USP),12601 Twinbrook

Pkwy.,Rockville,MD 20852-1790,http://www.usp.org.

8Available from International Organization for Standardization(ISO),ISO

Central Secretariat,Chemin de Blandonnet 8,CP 401,1214 Vernier,Geneva,

Switzerland,https://www.iso.org.

facturing systems are referred to throughout the rest of this

guide as critical aspects.

3.1.4 critical design elements(CDEs),n—components,

instruments,materials of construction,and features of an

engineered system that are necessary to consistently achieve

required process controls enabling manufacture of products

meeting critical quality attributes(CQAs).

3.1.4.1 Discussion—Examples of automation features in-

clude ability to alarm and to manage data.CDEs are identified

and documented based on technical understanding of the

product CQAs,process CPPs,and equipment design/

automation.CDEs are verified through commissioning and

qualification(C&Q).CDEs are the outputs of the design

development life cycle.

3.1.5 critical process parameters(CPP),n—a process pa-

rameter whose variability has an impact on a critical quality

attribute and therefore should be monitored or controlled to

ensure the process produces the desired quality.

3.1.6 critical quality attributes(CQA),n—a physical,

chemical,biological,or microbiological property or character-

istic that should be within an appropriate limit,range,or

distribution to ensure the desired (ICH Q8(R2))product

quality.

3.1.7 design reviews,n—planned and systematic reviews of

specifications,design,and design development and continuous

improvement changes performed as appropriate throughout the

life cycle of the manufacturing system.

3.1.7.1 Discussion—Design reviews evaluate deliverables

against standards and user requirements,identify problems,

and propose required corrective actions.The design should be

reviewed at pre-defined stages and appropriately documented

during development targeted to address specific issues includ-

ing hazards to be analyzed through quality risk management.

3.1.8 design qualification(DQ),n—a documented process

that verifies that the proposed design of the facilities,systems,

utilities,and equipment is suitable for the intended purpose and

is in compliance with EU GMP Annex 15 and FDA Guidance

for Industry Process Validation.

3.1.9 direct impact system,n—a system that directly impacts

product CQAs,or directly impacts the quality of the product

delivered by a critical utility system.

3.1.9.1 Discussion—All other systems are considered to be

not direct impact.

3.1.10 engineered systems,n—the term includes all systems

designed,delivered,and maintained throughout their life cycle

per GEP,including custom-designed,stick-built,catalog,and

commercial off-the-shelf systems.

3.1.11 general user requirements(GUR),n—are require-

ments related to process capacity,equipment availability,

environmental discharges,safety,and other typical non-GMP

requirements.

3.1.11.1 Discussion—GURs are typically defined in addi-

tion to the product and process user requirements(PUR)and

are collectively referred to as“general user requirements”in

order to distinguish them from those that may impact product

quality.General user requirements are managed through GEP.

2

摘要:

展开>>

收起<<

ThisinternationalstandardwasdevelopedinaccordancewithinternationallyrecognizedprinciplesonstandardizationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecommendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.Designation:E2500-25I...

声明:如果您的权利被侵害,请联系我们的进行举报。

相关推荐

-

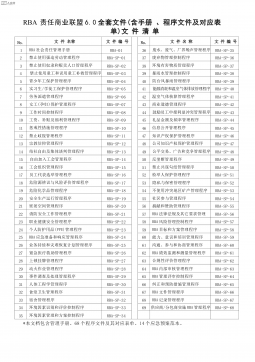

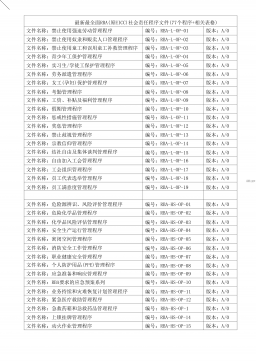

RBA8.0官方中文版VIP免费

2025-11-16 36

2025-11-16 36 -

新版RBA责任商业联盟一整套文件(含管理手册、全套程序文件及对应表单)

2025-11-17 40

2025-11-17 40 -

最新最全面RBA(原EICC)社会责任程序文件(77个程序+相关表格)

2025-11-17 44

2025-11-17 44 -

RBA-SP-067 供应商分包商实施RBA管理程序

2025-11-18 33

2025-11-18 33 -

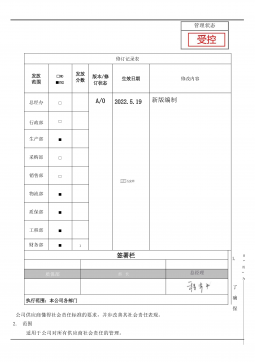

RBA-SP-066 记录管理程序

2025-11-18 29

2025-11-18 29 -

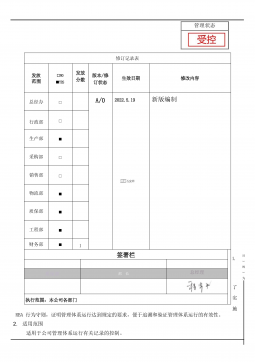

RBA-SP-065 文件管理程序

2025-11-18 25

2025-11-18 25 -

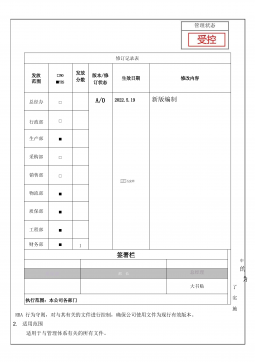

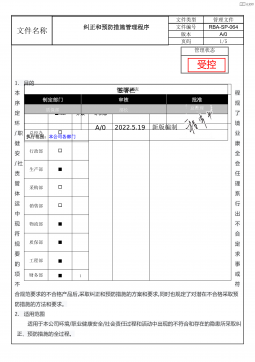

RBA-SP-064 纠正和预防措施管理程序RBA8.0

2025-11-18 26

2025-11-18 26 -

RBA-SP-063 管理评审控制程序

2025-11-18 24

2025-11-18 24 -

RBA-SP-062 内部审核管理程序

2025-11-18 39

2025-11-18 39 -

RBA-SP-006 劳务派遣管理程序

2025-11-18 44

2025-11-18 44

作者: 51zlzl

分类:法规规范

价格:80质量币

属性:20 页

大小:1.64MB

格式:PDF

时间:2025-11-21