供应商品质系统审核报告

第 1 頁,共 14 頁

供應商品質系統稽核報告

Supplier Name:

Factory location:

Assessment date:

No Check List

self score

celxpert score

1 2 3 4 5 1 2

1Quality System Requirements

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

1.11

1.12

1.13

是否適用

?

(Y/N)

是否適用

?

(Y/N)

Has the supplier defined and documented its corporate quality policy, objectives and commitments to quality?

供應商是否有定義並將公司品質政策、目標及對品質的承諾文件化?

Are procedures in place to ensure this quality policy is understood, implemented and maintained at all levels in the organization?

是否有程序書來確保品質政策被全公司了解,導入

並維持?

Has the supplier defined the responsibility, authority and interrelation of all personnel who manage, perform and verify work that affects the quality

of products, materials or services? (i.e. procedures, organization charts, quality manual )

供應商是否建立品管系統,含程序、組織圖、品質手冊?

Has the supplier appointed a management representative who has responsibility and authority for ensuring that a quality management system has

been implemented and maintained? 供應商是否有指派一

管理代表來確認品質管理系統被導入執行並維持?

Does the supplier carry out a comprehensive system of planned and documented internal quality audits?

是否有執行有計劃且有記錄之內部系統稽核?

Are the internal audits planned taking into consideration the status and importance of the process and areas to be audited as well as the results of

previous audits?

內部稽核是否考慮擬審核的過程和區域的狀況和重要性以及以往審核的結果?

Are the auditors qualified and ensured the ability objectivity and impartiality of the audit process? (e.g. auditors shall not audit their own work.)

稽核員是否有足夠的資格認可並保證了稽核過程的客觀性和公正性?(例如︰稽核員不能稽核他們自己的工作)

Are the correct actions taken without undue delay to eliminate detected nonconformities and their causes as well as the verification of the actions

and report of verification results?

供應商是否及時採取措施以消除內部稽核中發現的不合格及其產生的原因並驗証所採取對策和報告結果?

Has the supplier been audited by customer or 3rd party and the audit results been analyzed for improvement from a system level?

供應商是否進行過外部審核(第二方審核或第三方審核),稽核的結果是否已經從系統面進行分析改善?

Does the supplier conduct management reviews of the suitability and effectiveness of the quality management system at appropriate intervals?

(i.e. does the quality system meet customer requirements?) 供應商是否有在

每一個適當的階段來執行品質管理系統的適用性及有效性評估?

Does the management review include the verification of achievement of quality objectives and customer feedback?

管理評審是否包含了品質目標的達成狀況和顧客的回饋?

Does the management review include the results of the audits, process performance and product conformity?

管理評審是否包含了稽核的結果,過程的表現和產品的一致?

Does the management review include the status of preventive and corrective actions and follow-up actions from previous management reviews?

管理評審是否包含了預防和改善對策的狀況和上次管理評審的后續對策?

第 2 頁,共 14 頁

1.14

1.15

2Personnel Competence and Training

2.1

2.2

2.3

2.4

3Design Control

3.1

3.2

3.3

3.4

3.5

4Engineering Change Management

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

5 Document Control

5.1

Does the management review include the recommendations for improvement of quality management system and product related to customer

requirements?

管理評審是否包含了對品質管理體系和與顧客要求有關的產品改善的建議?

Has the supplier established the appropriate and effective communication processes within the organization?

供應商是否在組織內建立了適當並有效的溝透過程?

Is there a system that identifies training requirements for all personnel affecting the quality of the product?

是否有一能識別會影響產品品質之相關訓練需求之系統?

Does the supplier evaluate the effectiveness of the training taken and maintain the training records?

供應商是否有評估培養訓練的效果並維護其訓練記錄?

Does a system exist for determining which personnel are qualified for a job function? 是否有一系統能決定人員

是合適於某一工作?

Is there a system to disqualify and re-qualify personnel in a job function? 是否有一系統能剔除及

重新認證人員的工作任務?

Is the design control procedure established to plan, control, review, verify and validate the design of the product?

供應商是否建立設計管制程序來規劃,控制,評估,驗証和確認產品的設計?

Are there procedures to control and verify the design of the product to ensure it is meeting all requirements?

驗證產品的設計並確保它符合所有的要求。

Are there plans that identify the responsibility for each design and development activity? 針對每一設計及發展活動

,是否有能識別責任的計劃?

Is there a requirement to verify the product meets design specifications prior to mass production? (e.g., design review/verification)

是否有在量產前確認產品符合設計的規格?

Are the records for design review properly documented and maintained? 設計評估是否被適當地

記錄並維護?

Is there a procedure to govern engineering changes? 是否有一程序來監督

工程變更?

Are engineering changes reviewed and approved by authorized personnel prior to implementation?

在導入前,工程變更是否被評估並由被授權的人認可?

Are the engineering change notifications distributed to all affected functional areas once approved?

是否工程變更通知會分派到所有相關的單位?

Is there a system to ensure engineering change notifications are being implemented? 是否有一系統確認工程變更的

導入?

Is there a system to verify the effectiveness of engineering changes? 是否有一系統來確認工

程變更的有效性?

Is there a process defined such that no modification to the Product occurs without Customer’s prior written consent?

製程中是否有清楚定義 , 沒有經由客戶同意不修改產品

中任何變更 。

Is there a process that ensures all customer-approved engineering changes are implemented?

是否有一程序擔保當工程變更時所有客戶均認可 ?

Is there a notification procedure for process changes? 當製程變更時,是否有一

程序通知書 ?

Is there a process to ensure product modifications follow customer requirements? 是否有

一程序擔保產品變更時,遵循客戶要求?

Do these procedures ensure that pertinent documents are available to personnel at all locations?

是否有確認所有人都能容易取得相關文件?

第 3 頁,共 14 頁

5.2

5.3

5.4

5.5

5.6

5.7

5.8

6Supplier Quality Control

6.1

6.2

6.3

6.4

6.5

6.6

6.7

6.8

7 Product Identification and Lot Traceability

7.1

7.2

7.3

8 Process Control

8.1

8.2

8.3

Do these procedures ensure that all obsolete documents are promptly removed from all points of issue or use?

是否確認有將不適用的文件立即移除?

Are quality documents reviewed and approved for adequacy by authorized personnel prior to issue?

是否有經授權的人員來評估並認可品質文件的足夠性(完整性)

Are there documented procedures for control of quality records? 是否有

一程序來控管品質記錄?

Are all quality records identified, indexed, filed, collected, stored, maintained, and disposed after stated period?

品質記錄是否可被識別、索引、歸檔、收集、儲放及保存並在一定時間後報廢。

Are quality records maintained in such a way that they are readily retrievable? 品質記錄是否隨時可取

用?

Are quality records stored in such a way that deterioration is minimized and loss is prevented?

品質記錄、保存方式是否可使損壞減至最小及避免損失?

Have retention times of quality records been established and recorded? 品質記錄保存期限是否有定

義並記錄?

Are up-to-date records kept of acceptable/approved subcontractors? 是否有最新的合格廠商名

錄?

Has the supplier defined the criteria of selection & qualification process for its sub-suppliers and sub-contractors?

供應商是否定義了對其下游廠商和外包商的選定標準和評定流程?

Has the supplier conducted quality survey and audit for its sub-suppliers and sub-contractors qualification?

供應商是否對其下游廠商和外包商進行品性調查和稽核來評定其資格?

Is there a procedure for part qualification? (i.e. tooling qualification, inspection method, inspection quantity, etc.)

是否有零件承認程序?(如工具、檢驗方式及數量等)

Has the supplier established the effective communication processes with its sub-suppliers and sub-contractors and up-to-date delieried

requirment to them?

供應商是否建立了與其下游廠商和外包商進行有效資訊溝通的流程,並及時傳達要求?

Has the supplier defined the periodical review and audit process for its approved sub-suppliers and sub-contractors' quality system and implement

it ?

供應商是否定義了對其合格的下游廠商或外包商之品性系統進行定期檢查並實地稽核的流程並予以執行?

Has the supplier defined the proper process to disqualify an approved sub-supplier or sub-contractor as well as re-qualify it?

供應商是否定義了對其合格的下游廠商或外包商取消資格和重新賦予的流程?

Has the supplier periodically ranked the approved sub-supplier and sub-contractor based on supplier's criteria of cost, quality, technology and

service?

供應商是否對其合格的下游廠商和外包商進行成本、品性、技術和服務方面的定期評定?

Are there procedures defining product identification requirements for all products 是否有能識別產品的程序

Are in-stock and in-process materials properly identified and controlled? 倉庫及在製品能否被分辨

及管制?

Where traceability is a specified requirement, do individual products or batches have a unique identification?

當追溯性是一個特定的要求時,每一 LOT 是否有特殊的識別方式?

Are there work instructions defining the manner of production and installation for each process/station?

是否有工作指導書?

Do the work instructions clearly specify the machines, equipment, tools, fixtures, and program to be used?

是否清楚列入機器、設備、工具、治具及所用的程式?

Are quality documents (e.g., QC-flow/work instructions) revision controlled and approved by authorized personnel prior to issue?

品質文件是否有版本控制並由被授權的人認可?

摘要:

展开>>

收起<<

第1頁,共14頁供應商品質系統稽核報告SupplierName:Factorylocation:Assessmentdate:NoCheckListselfscorecelxpertscore12345121QualitySystemRequirements1.11.21.31.41.51.61.71.81.91.101.111.121.13是否適用?(Y/N)是否適用?(Y/N)Hasthesupplierdefinedanddocumenteditscorporatequalitypolicy,objectivesandcommitmentstoquality?供應商是否有定義並將公司品質...

声明:如果您的权利被侵害,请联系我们的进行举报。

相关推荐

-

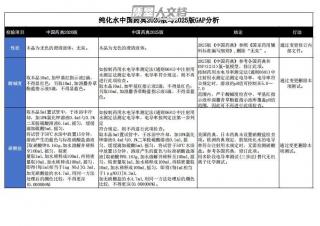

纯化水中国药典2020版与2025版GAP分析VIP免费

2025-04-18 308

2025-04-18 308 -

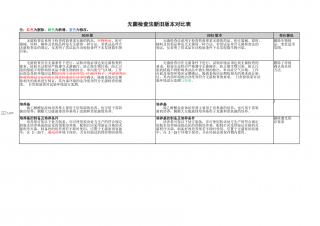

无菌检查法对比表(2025版药典 VS 2020版药典)

2025-09-27 375

2025-09-27 375 -

1101无菌检查法对比表(2025版药典 VS 2020版药典)

2025-09-29 278

2025-09-29 278 -

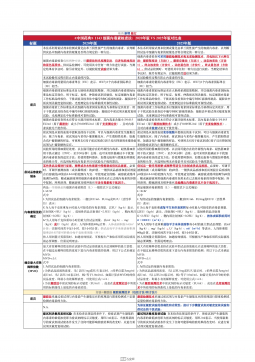

1143 细菌内毒素检查法对比表(2025版药典 VS 2020版药典)

2025-09-29 614

2025-09-29 614 -

ECA-污染控制策略指南(中英文)-202202VIP免费

2025-11-04 62

2025-11-04 62 -

TR-26-2025-Sterilizing-Filtration-of-Liquids液体的灭菌过滤(中英文对照版)VIP专享

2025-11-06 393

2025-11-06 393 -

TR-26-2025-Sterilizing-Filtration-of-Liquids液体的灭菌过滤(英文版)VIP免费

2025-11-06 123

2025-11-06 123 -

PDA-TR49-生物清洁验证-中英文翻译

2025-11-19 79

2025-11-19 79 -

硫酸艾玛昔替尼片(CXHS2300097)说明书VIP免费

2025-11-26 167

2025-11-26 167 -

达格列净片说明书VIP免费

2026-01-13 23

2026-01-13 23

作者: 51zlzl

分类:体系管理

价格:60质量币

属性:14 页

大小:96.5KB

格式:XLS

时间:2025-11-25